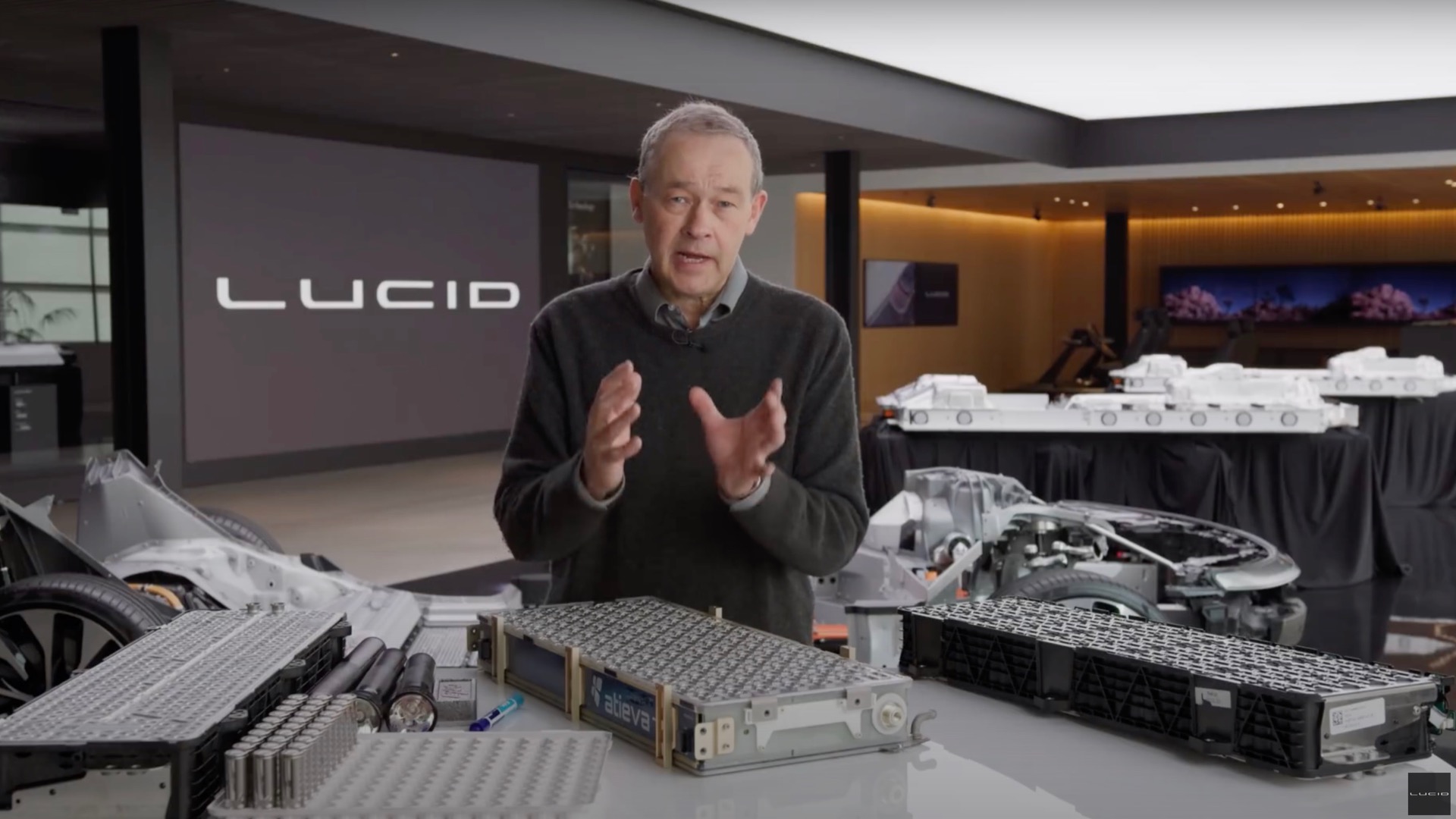

Lucid CEO Peter Rawlinson is seen over a 36-minute video talking about every aspect of the Lucid Air battery pack and its ability to reach a range of 520-mile. It is considered the best EV premier ever as he talks about energy, power, cells, modules, and many more.

Rawlinson starts with the basics: energy and power. Energy represents whether work—such as running up a hill—can be accomplished, while power represents how fast it can be done, Rawlinson explains. In electric cars, power is expressed in kilowatts (often converted to horsepower for comparisons with internal-combustion vehicles) while energy is expressed in kilowatt-hours.

Lucid leans on cylindrical cells, as do Tesla and Rivian—partly for their more consistent cooling behavior. Each 2170-format cell has about 17 watt-hours of energy, which Rawlinson reckons could propel the Air about 140 yards, in case you were wondering.

Reaching the range

To meet Lucid’s original range target of about 400 miles, Rawlinson and company calculated that they would need about 6,000 cylindrical cells, which were then arranged in 300-cell modules mounted under the floor. Each module has 42 volts, for a total of 924 volts in the 22-module Air Grand Touring and Dream Edition packs.

Additionally, this is a higher voltage than other EVs, and the advantage of that has to do with Ohm’s law, the fundamental law describing energy flow through electrical circuitry. Because Ohm’s law states that heat losses are proportional to current squared, decreasing current allows for more power with greater efficiency, Rawlinson explains. Doubling voltage allows for current to be halved, which Rawlinson calls a “core tenet” of Lucid’s engineering philosophy. “There’s no substitute for voltage in terms of efficiency,” Rawlinson says, referencing Lucid’s main focus. High voltage helps the Air achieve a very high charging rate, but also produces system-wide efficiencies, he adds.

Furthermore, Lucid uses a somewhat different cooling system than other automakers, placing cells very close together and using cooling plates at the cell ends rather than running coolant channels between the cells. Again, it’s about efficiency. Modules with coolant channels are difficult to manufacture with the necessary precision, and cells tend to disperse more heat at their ends anyway, Rawlinson explains. Lucid builds its own modules and packs in Arizona, near its assembly for the cars themselves. It’s a process it’s designed to scale up to many hundreds of thousands of vehicles annually. Also, it is not surprising that Lucid is so focused on battery tech. It used to be Atieva, a battery company, and in some ways, the Air builds on the company’s Formula E experience.